I tried cleaning the hood latches and squirting in grease from above, but there just wasn't access to really do it well. So, I decided to change out the cables, and remove the latches so I could really clean and lubricate them. Fair warning - it's a pretty miserable job, although it will be easier if I ever have to do it again.

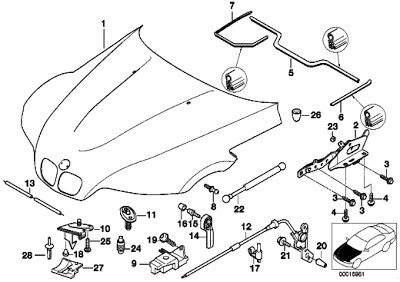

It's difficult to take pictures on the car that show what I'm talking about, so here's a clip from www.PenskeParts.com - a great site that shows the same parts diagrams as the realoem.com site, but much easier to navigate. The prices are more up-to-date, also.

We're interested in #9, the latches (there are two, even though the picture shows only one, and they are different left and right), #13, the Bowden cable that connects the two latches, and #12, the cable that goes into the car.

The Bowden cable runs through a channel in the sheet metal that is totally inacessible. One Internet "expert" had you remove some fasteners and bend the metal up, but I wasn't going to do that! I discovered that the trick is to remove the fasteners from both latches, and then slide them side to side to gain access to remove the cables.

Oh, but wait, there's no access on the driver's side. I had to remove the headlight to do that. It's pretty well documented elsewhere, so no pictures of that. Just be sure to hold the plastic nuts as you remove the screws at the top, so your headlight alignment won't be affected.

The picture above is of one of the two latches. It is held in by special star-drive screws (also called Torx screws). Of course, I didn't have that tool. Since I have a Harbor Freight store just a few miles from my house, it was easy to pick up several sets of special sockets for the BMW.

I recommend picking up all four of these if you are going to work on a modern BMW. The one on the left is metric hex wrenches - you'll need the 14mm and maybe the 17mm to change gear oil. The next set is the Torx bits - I think the T30 was the one for the hood latches. The other two sets are various depths and sizes of the female star wrenches, which are called E-drive for some reason. I needed them working on the ABS system.

Once the latches were loose, I was able to detach the cables, but it wasn't easy. 12 years of dead grease had them pretty well stuck in place. It also takes a good bit of pressure to lift the cable out of the slot. This picture is fuzzy (sorry), but here's what finally worked: I used a bent pick like a dental pick, hooked it under the cable, and then pulled the round "bullet" on the cable end out of the slot:

That photo is posed, of course - I had to do that while the cable was still in the car. The Bowden cable is held by two clips up in the channel, and I could NOT get them to pop out. However, the cable was easily able to slide out of the clips once it was detached from both latches.

Here are the latches on the bench - once I had them out, I used most of a can of brake cleaner and a brass brush getting all the crud out of them. Then, I sprayed them liberally with white lithium grease, which goes on as a liquid, but then solidifies.

It was easy to put the Bowden cable on the passenger side latch and then feed it through the channel, but how was I going to get the cable back into the clips? The answer turned out to be a tool that you probably already have too - one of those long cable things for picking up dropped parts. You press the button on the end, and these wire hooks come out the other end:

I slid the pickup tool through the grill opening and grabbed the Bowden cable with it - that allowed me to precisely place the cable at the clip. Then I used a long screwdriver to "click" the cable into the clip.

Now, all that was left was to replace the cable into the passenger compartment. I was really worried about this part, because the path was totally inacessible inside the car. I had removed the various plastic panels to gain access, but there was an incredible mass of wiring and relays that blocked the way. But when I removed the cable pull, I realized it was not really broken - it had just fallen apart from being pulled crooked. In the picture below, the little brass clip nut had pulled off the post for the handle. I found an 8mm deep socket that perfectly fit over it, and used a mallet to drive it back in place. I could then reuse the cable from the inside.

So, after all this effort, I put everything back together, and... it's a little better. Still stiffer than I wish it was. I think I'll engage the help of a body man to check the alignment of the hinges and catches. The Internet suggests that adjusting the hinges all the way at the other end of the hood can make a difference in the effort. But at least now I'm not so concerned that I'm going to be locked out of my engine compartment!

EDIT: See Part 2 for what finally fixed this problem!

No comments:

Post a Comment