It is an absolute mystery why I had to create this blog post! I have recruited experts from coast to coast, and they are as befuddled as I am. In Part 70, I told of installing an MGA rear end because I wanted to experiment with a different gear ratio. That is a common swap, but when I went to install the driveshaft later, it wouldn't fit - it wouldn't even drop in place!

I did a ton of measurements, and recruited Jake R. in California to take measurements from his car. In this photo, we compared the distance from the axle flange to the rear crossmember. We were identical at 7-3/4". Similarly, we both measured from the front of the rear end near the spring mount to the center of the bolt that located the front of the leaf spring, and were identical at 18-5/8".

That started one of the most stressful, yet rewarding, projects I've experienced. The idea was that I would install the driveshaft in my Logan lathe, using a four-jaw chuck and a steady rest to align it, and then shorten it, clean up the welded end, put it back together, carefully align it, and weld it back together. Jake assured me that if the alignment was carefully done, the driveshaft would not need balancing. He cited personal experience with dozens or hundreds of shafts over his career.

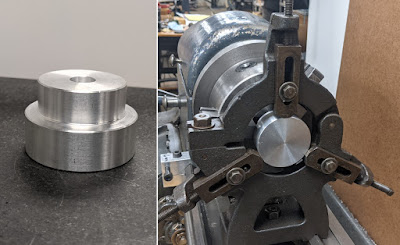

Jake gave me some good advice to get started, including this technique to get the steady rest correctly aligned. You make a plug that is exactly the diameter of the driveshaft tube, and use that to preset the steady rest on center. Then you move the steady rest to the far end of the lathe to hold the "back end" of the driveshaft. I also made a custom sleeve to protect the splines of the yoke shaft from the chuck, and you can see it peeking out in a couple of the photos below.

Aligning a four-jaw chuck is a fussy skill, and I was terrible when I started the project. Basically, you move matching jaws a minute amount until there is no indication on the dial indicator when you rotate the shaft. I got pretty good at it after three long sessions of doing it over and over.

Once I had it aligned, I chose a spot to cut, and used a parting tool to remove the long rear end of the shaft.

Once that was accomplished, it uncovered a center on the shaft, and I could move the tailstock forward and put a matching center in it to hold the shaft steady while I cleaned up the remainder of the weld. I had already used the parting tool to cut the shaft right behind the weld also, and in my inexperience I cut deeper than I needed to. No harm done, and I later realized that it made a nice groove for weld to penetrate into. That short remaining stub from the tube was a tight press fit, and I had to slit it with a thin cutting wheel in a Dremel tool to get it off.

Finally, I had the pieces in hand, and that's when I discovered the driveshaft was just a couple of inches too long to fit in my press. I had to tap the stub shaft back into the tube by hand. Troy Nace was there that night, and he heated the tube with a propane torch to expand it a bit. That helped. Then we briefly put the driveshaft in place to make sure the clearance was good. It was just right!

Then started the VERY laborious process of getting the shaft perfectly aligned. Jake was a kind and patient teacher for that. The process that worked for me was quite a trial. I would install the driveshaft in the lathe and carefully zero out the four-jaw chuck. Then I'd move the indicator to the tube and find and mark the high spot. Then I'd remove the driveshaft, take it to the workbench, and tap the splined shaft with a dead blow hammer opposite the high spot. Over and over and over...

When I started, the shaft was 0.090" out of alignment - enough that you could easily see the misalignment with the naked eye. By the end of the first three-hour session, I had it down to 0.012". I asked Jake if that was good enough, and he thought I could get it better. The next session, I got it worse for the first 2 hours, but finally I gave it just the right tap and got 0.005", plus an occasional bump due to flaws in the tube. Jake said it would get no better than that.

Check out this 30-second video: in the first segment, you see the zero runout at the machined shaft, then the good-enough runout on the tube, and finally the runout at the far end, which is even better. https://youtu.be/OEHaaP98Ugw

And then it was time to weld... and I did test welds on the offcut from the tube, and then more test welds, and decided... time to call in the cavalry. This is Duane D., a pro welder who is a member at the makerspace Make717. He very kindly agreed to come weld it for me.

While the driveshaft was still in the lathe, I reinstalled the protective plywood and used abrasive strips to sand the entire driveshaft. Then I primed and painted it - after all, that's what the driveshaft shop would have done. I even greased the U-joints and spline while it was on the bench and easy to reach.

Today I got the driveshaft back in the car and reinstalled the exhaust system, and then it was time for a test. I lowered the car onto jack stands so the driveshaft angle would approximate driving down the road, with the lift pads hovering underneath the frame for added safety, and then started testing under engine power. Idling at 800 RPM in first, then second, then third, and finally fourth gear. All seemed fine, so I started adding RPM. You can't tell from a still photo, but in that photo below the driveshaft is rotating at about 3000 RPM.

That's just over 50 MPH. Here's a link to a brief video that shows it, but the driveshaft runs so straight it still looks like it is sitting still! https://youtu.be/IYPdgibtYiY

I still can't believe I did it, but I did. I'll have to shorten another driveshaft when I install the overdrive trans next winter, so I'll keep practicing - maybe by then I can even do the welding myself.

ADDENDUM: Later, when I could test drive, I hit a big bump and heard the unmistakable sound of the driveshaft scraping. I investigated, and saw that it couldn't have been hitting the crossmember. I finally realized it had bumped the bolts for my custom seatbelt installation! I shortened the bolts, and no more scrape. In the left photo, you can see which bolt contacted from the debris on the end of the threads. The red paint was added to tell me where to cut when shortening.

No comments:

Post a Comment